- #GRBL CONTROLLER ALARM LOCK HOW TO#

- #GRBL CONTROLLER ALARM LOCK SERIAL#

- #GRBL CONTROLLER ALARM LOCK DRIVERS#

- #GRBL CONTROLLER ALARM LOCK UPDATE#

The punching stroke will be stationary as usual. We try to make a wire bending machie, but we need to connect it with grbl to make any shape, how we can make its software codecan you help us? Question 4 months ago on Step 3. But in the original PCB inI dont that problem, and the firmware is the same. Hi, I have the same problem in one PCB from cronos maker. Participated in the First Time Authors Contest Question 2 months ago on Introduction. Hopefully This instructables was helpful and your cnc machine is up and running! When you have edited the config file you need to reupload the sketch to your board. The file has instructions and should be pretty straight forward to edit. You find the config file in the arduino library folder for grbl. Some settings like corexy setup,variable spindle needs to be changed trough the config. You should see a message like this "Grbl x.

#GRBL CONTROLLER ALARM LOCK SERIAL#

To communicate with your board you need to open the arduino ide serial monitor. Now with firmware on your board you need to adapt grbl to your specific machine.

#GRBL CONTROLLER ALARM LOCK HOW TO#

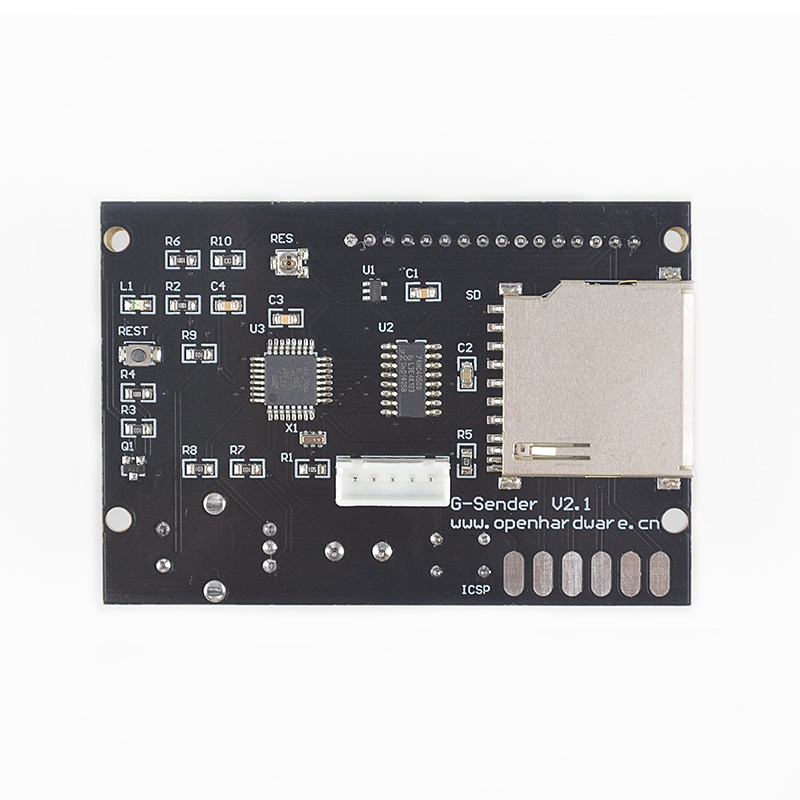

A new sketch will open with instructions on how to flash grbl to your board. Grbl is now installed as a arduino library. There are also arduino nano based boards made specially for laser cutting. Building your own is pretty easy but can take alot of time.

#GRBL CONTROLLER ALARM LOCK DRIVERS#

To connect your motor drivers and arduino you can use a pre-made board like the popular arduino uno cnc shield or build your own. Its a good idea to stay clear of the easy drivers. Some popular choices are a and drv for small motors like nema 14 or 17, but should not be used with more powerful motors like nema23 and higher. To drive stepper motors you need some sort of driver. The arduino mega is used in alot of 3d printer because of its more powerful processor but because of the relatively easy tasks of a cnc mill the arduino uno is enough. Grbl is compatible with all atmega based arduino boards, meaning that you could use a uno or a nano but not the mega as its atmega based. Inventables Community Forumīecause GRBL arduino boards you just hook it up to a free usb port. Most industrial cnc machines uses parallel port controller that requires Those big purple connectors.

#GRBL CONTROLLER ALARM LOCK UPDATE#

For example, to update the X step/mm setting $100 to a value of 316.GRBL uses gcode as input and outputs signals via the arduino pins. Go line by line and update the GRBL settings from the file you saved by typing $ with the setting number followed by the new setting value and then pressing enter. Look for the GRBL v1.1 settings in the Console Tab. How to update grbl settings step by step? It allows us to use an Arduino to run our CNC machines. What exactly does it do? Basically, the software when loaded onto an Arduino creates the heart of a low cost high performance cnc controller.

I am not aware of any comparable software. GRBL software powers the Arduino CNC revolution. What does grbl software do for the arduino? What you need… 2) Stepper Motor Drivers – the bridge between the Arduino and stepper motors that actually move your machine. Click here for a step by step guide to setup your DIY CNC Controller. In order to create a cnc controller using GRBL software, we need a few additional items outlined below. What do i need to make a cnc controller with grbl?

Our website provides a free download of Grbl Controller 3.6.1. The utility is compatible with older processing units. Custom commands are sent to individual controllers or entire systems. Frequently Asked Questions Is there a free version of the grbl controller?Īccess and control various models of CNC hardware cush as milling machines by sending configured signals via the suite managing native GCode.

0 kommentar(er)

0 kommentar(er)